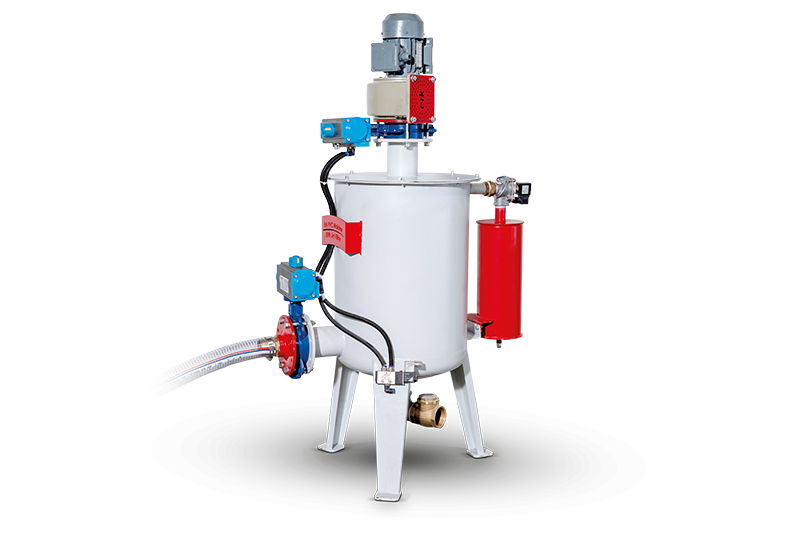

EPM-JET Filter

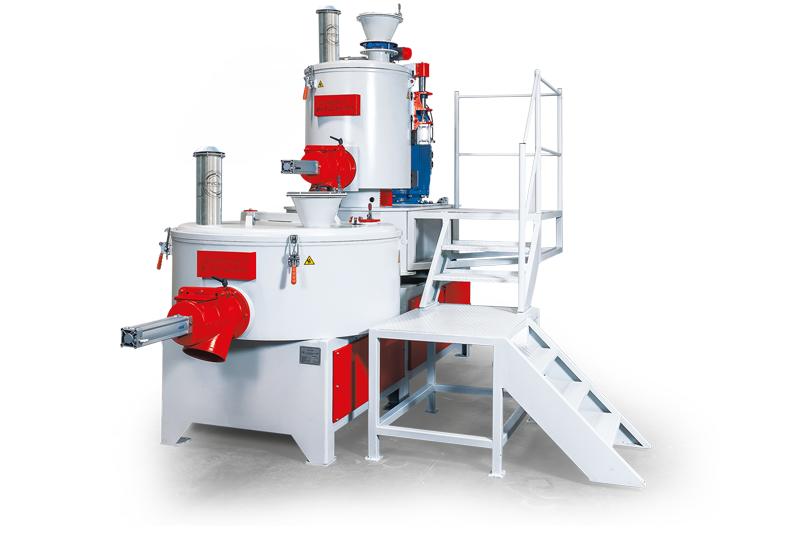

Plastic Raw Material Dehumidifying & Mixing Stabilization System

Product Overview

ERK PVC Makine developed the EPM-JET Filter to remove moisture released during the hot-mixing phase.

By extracting humidity while the heater mixer is running, the system prevents lumping/agglomeration and significantly improves batch homogeneity and process stability.

The next-generation EPM-JET series maintains mixer energy efficiency while ensuring uniform dispersion of additives.

This results in higher product quality, reduced scrap and steady process parameters across PVC and plastic compounding lines.

Applications

- PVC & plastic raw material mixing lines

- Heater mixer installations (hot mixing)

- Pre-granulation preparation lines

- WPC (wood-plastic composite) compounding

- Powder raw materials and additive processes

Technical Specifications

| Model | EPM-JET FILTER |

| Working Principle | On-mixer dehumidification & forced air circulation |

| Dehumidifying Capacity | 75 kg/hour |

| Power Supply | 0,55 kW |

| Filtration | Stainless steel body + heat-resistant filter element |

| Typical Materials | PVC, WPC, masterbatch, powder additives |

Key Advantages

- Stable production by extracting moisture during mixing

- Prevents lumping/agglomeration

- Higher homogeneity and product quality

- Low maintenance, long service life

- Easy retrofit to existing mixer systems

Conclusion

EPM-JET Filter is a performance-driven engineering solution that boosts mixer efficiency, process safety and homogeneity across PVC and plastic mixing lines.

High Quality Products

Expert Team

Superior Technology

Excellent Support

Erk Pvc Makine