ERK PVC MAKİNE

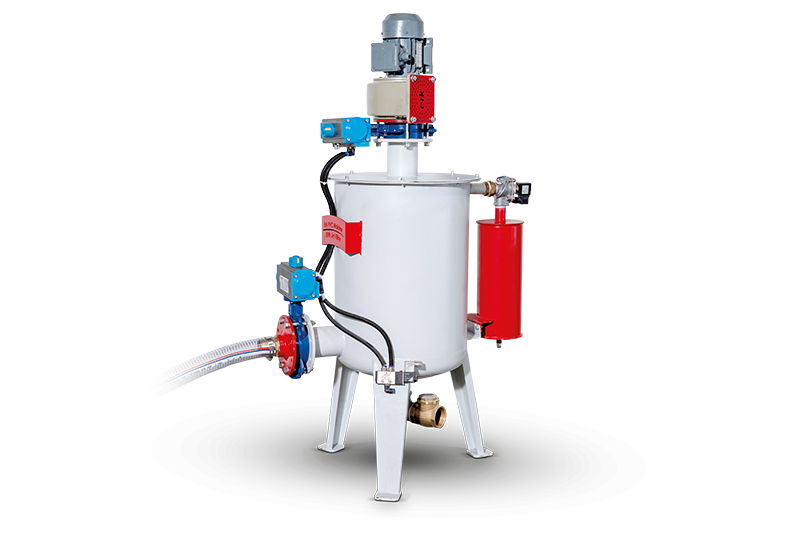

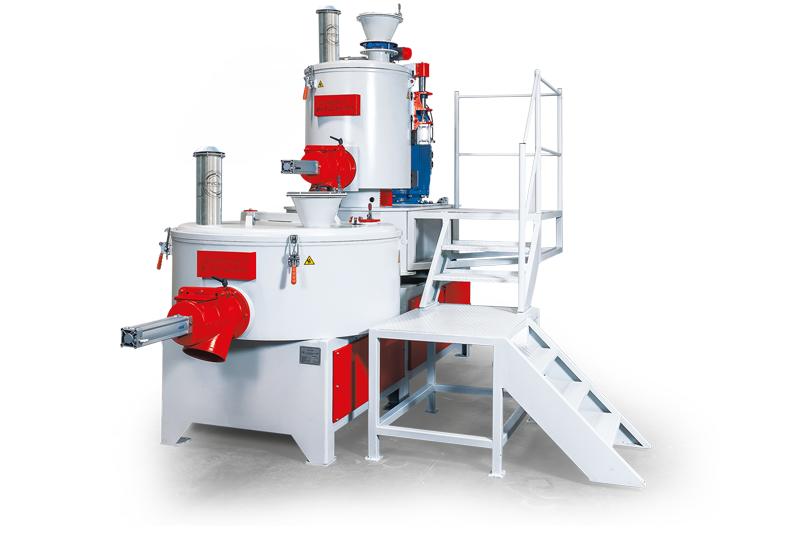

EPM-V VERTICAL MIXER SERIES

The initial phase of PVC production is mixing. To achieve a healthy manufacturing process, obtaining an optimally homogenous formulation is essential. Leveraging its expertise, Erk PVC Machinery stands as a leading player in the PVC manufacturing sector. Through its innovative GM-TURBO Mixer series, Erk PVC Machinery presents you with the ultimate homogenous mixture and speed.

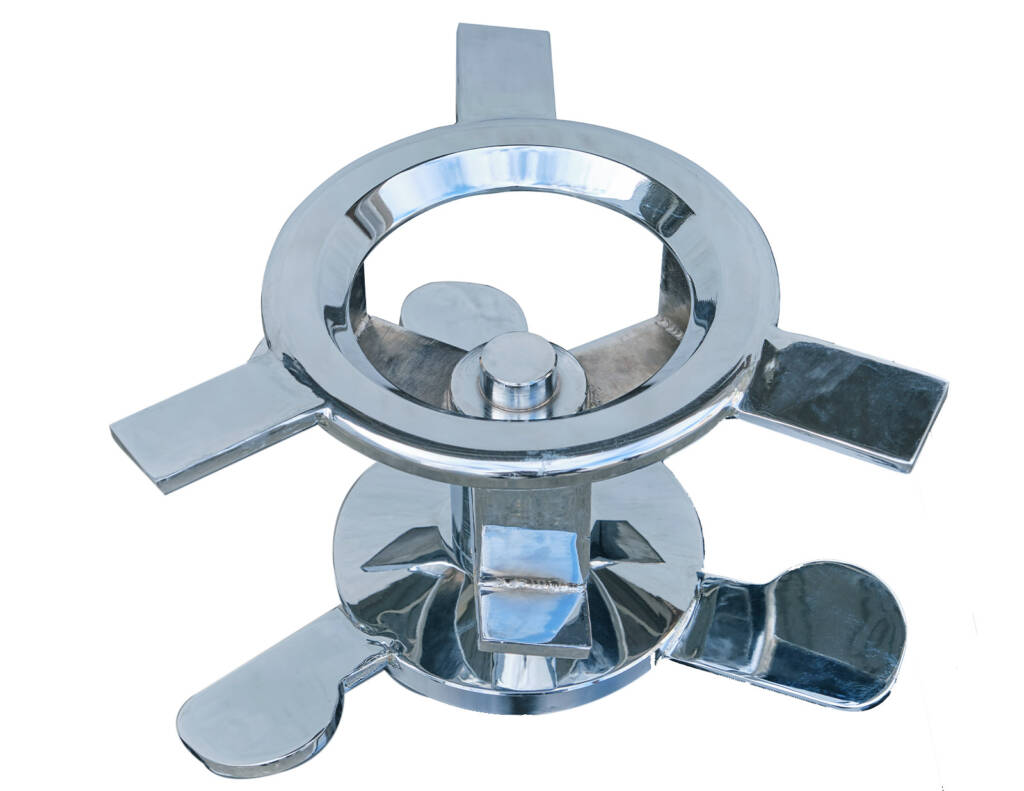

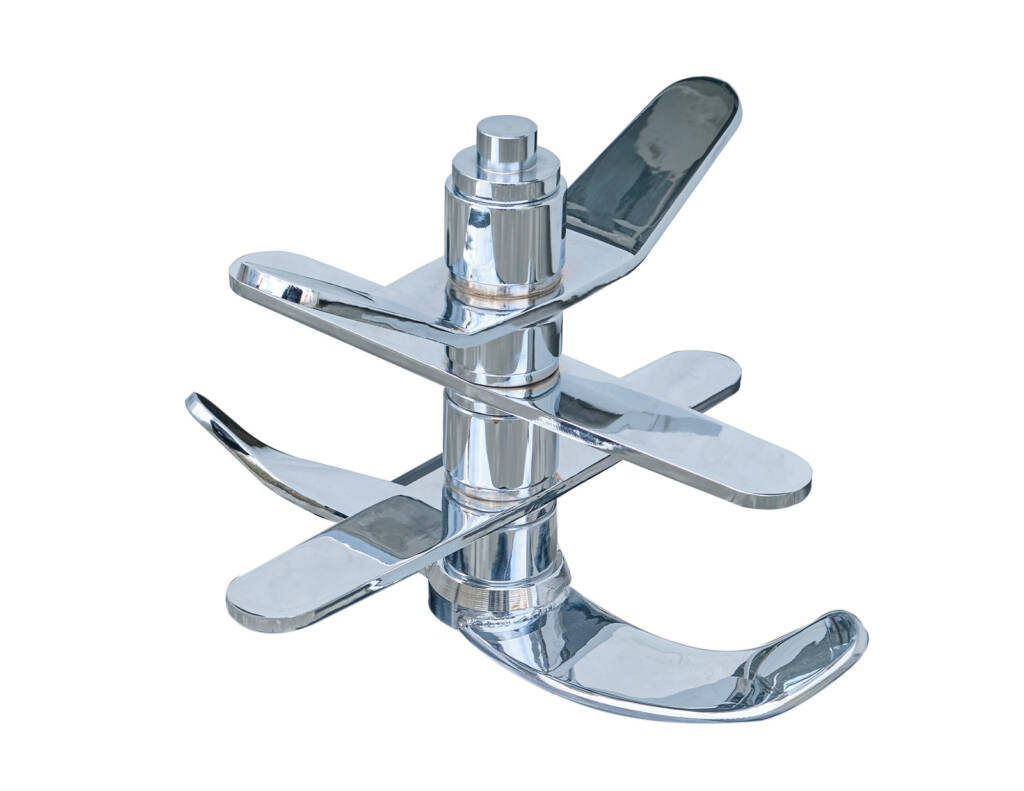

As it is widely recognized, the most critical aspect of mixing lies in the impeller design of the mixer. With substantial field experience, ERK PVC Machinery shares its knowledge and suitable impeller models tailored to both soft and rigid formulation values, enabling seamless production for you.

How it works?

High Quality Products

Expert Team

Superior Technology

Excellent Support

| EPM - MIXER MODEL V-H | EPM-V100 FV / SS | EPM-V150 FV / SS | EPM-V200 FV / SS |

| Production & Capacity ( Charge / Hour ) | 3-4 | 3-4 | 3-4 |

| Production & Capacity PVC+Additives Kg. | 100 | 150 | 200 |

| Heater Mixer Volume Lt. | 300 | 450 | 540 |

| Heater Mixer Motor Power kW | 45 | 75 | 90 |

| Cooler Mixer Volume Lt. | 520 | 700 | 850 |

| Cooler Mixer Motor Power kW | 5.5 | 7.5 | 11 |

AREAS SUITABLE FOR USE IN PRODUCTION

- PVC Door and Window Profiles

- PVC Curtain Rails

- PVC Cable Trays

- PVC Cable

- PVC Waste and Clean Water Pipes

- PVC Irrigation Hoses

- PVC Waterproofing Materials

- PVC Floor Coating

- PVC Foil

- PVC Tarpaulin

- Wood Composite Panel (WPC)

- Metallic Powder Coating (Bonding Mixer)

Erk Pvc Makine